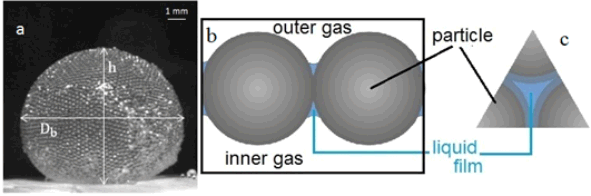

In line with the pioneer work of Pickering, we succeeded recently to produce new objects which can be described as gas pockets in air and named gas marbles. They are made of gas surrounded by a layer of grains constrained by thin liquid film in gas environment. The exceptional mechanical strength of their granular shell and its low gas permeability promise them to many applications. Among these, we note here that using gas marbles can be relevant for the generation of materials with hierarchical porosity. Moreover, these new hollow marbles offer a promising route to new vibration dampers.

Gas marbles were created by closing over itself after detachment under gravity of a granular film created by dipping and removing of a solid horizontal frame through a particle raft at the interface of a soap solution.

As part of a collaborative project (ANR PhyGaMa), our objective is to study the physics of gas marbles. At the microscale, three physical mechanisms inducing (possibly multicore) interactions between grains are at play: capillarity, grains contacts and viscous dissipation (in the liquid film and at the liquid/gas interfaces). The existence of gas marbles raises the following fundamental issues: How microstructure of the dispersed phases and microscale interactions are related and affect the macroscale behaviour of the materials? Are gas marbles and other ternary systems (unsaturated wet granular material, Pickering foams and granular foams) one class of material in a sense that they obey the same constitutive laws but with different state parameters defined by the physic at play at the microscale?

Related Papers :

– Gas Marbles: Much Stronger than Liquid Marbles, Y. Timounay, O. Pitois, F. Rouyer, Phys. Rev. Lett. (2017). doi:10.1103/PhysRevLett.118.228001

– Opening and retraction of particulate soap films, Y. Timounay, E. Lorenceau, F. Rouyer, EPL. (2015). doi:10.1209/0295-5075/111/26001.

– Low gas permeability of particulate films slows down the aging of gas marbles, Y. Timounay, E. Ou, E. Lorenceau, F. Rouyer, Soft Matter. 13 (2017). doi:10.1039/c7sm01444a.