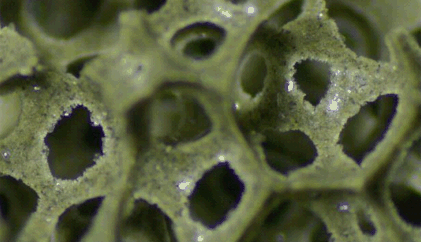

Cement foam advantages compared to normal concrete are its low density, low material need and thermal insulation capacity. To better understand how the morphology of cement foam affects its properties, we aimed to produce solid samples with well controlled structure. This involved two steps: (i) the creation of fresh cement foam with chosen structure, and (ii) the stability of this structure up to cement hardening. First step was ensured by our preparation protocol, and second step was investigated during the PhD thesis of Blandine Feneuil (2015-2018).

First, we studied the interaction of surfactants and cement paste. Some surfactants cannot stabilize foam in cement paste highly alkaline solution. Some others, mainly anionic surfactants, adsorb on cement grain surface, which modifies interactions between cement grains and consequently the yield stress of the cement paste. At low surfactant concentration, cement grain surface becomes hydrophobic and the yield stress increases due to hydrophobic attraction between cement grains. At high surfactant concentration, adsorbed micelles create a steric repulsion between cement grains and make cement paste yield stress drop.

Then, we focused on cement foam stability, at air content 83%. We first studied three series of experiments at given water-to-cement ratio and bubble size. For each series, the yield stress of the cement paste was changed by addition of superplasticizer or high amount of anionic surfactant. Unexpectedly, the best foam stability was obtained for relatively low yield stress. Rheological measurements on the fresh cement foams allowed us to understand this improved stability as a consequence of the reorganization of cement grains into denser packing. In a second part on stability, we studied the influence of bubble size, water-to-cement ratio and surfactant content. A stability criterion was defined from the bubble size and the interstitial cement paste yield stress.

Related Papers:

– Effect of surfactants on the yield stress of cement paste, B. Feneuil, O. Pitois, N. Roussel, Cement and Concrete Research (2017) 100, 32–39

– Stability criterion for fresh cement foams, B. Feneuil, P. Aimedieu, M. Scheel, J. Perrin, N. Roussel, O. Pitois, Cement and Concrete Research (2019) 125, 105865.

– Optimal cement paste yield stress for the production of stable cement foams, B. Feneuil, N. Roussel, O. Pitois, Cement and Concrete Research (2019) 120, 142-151