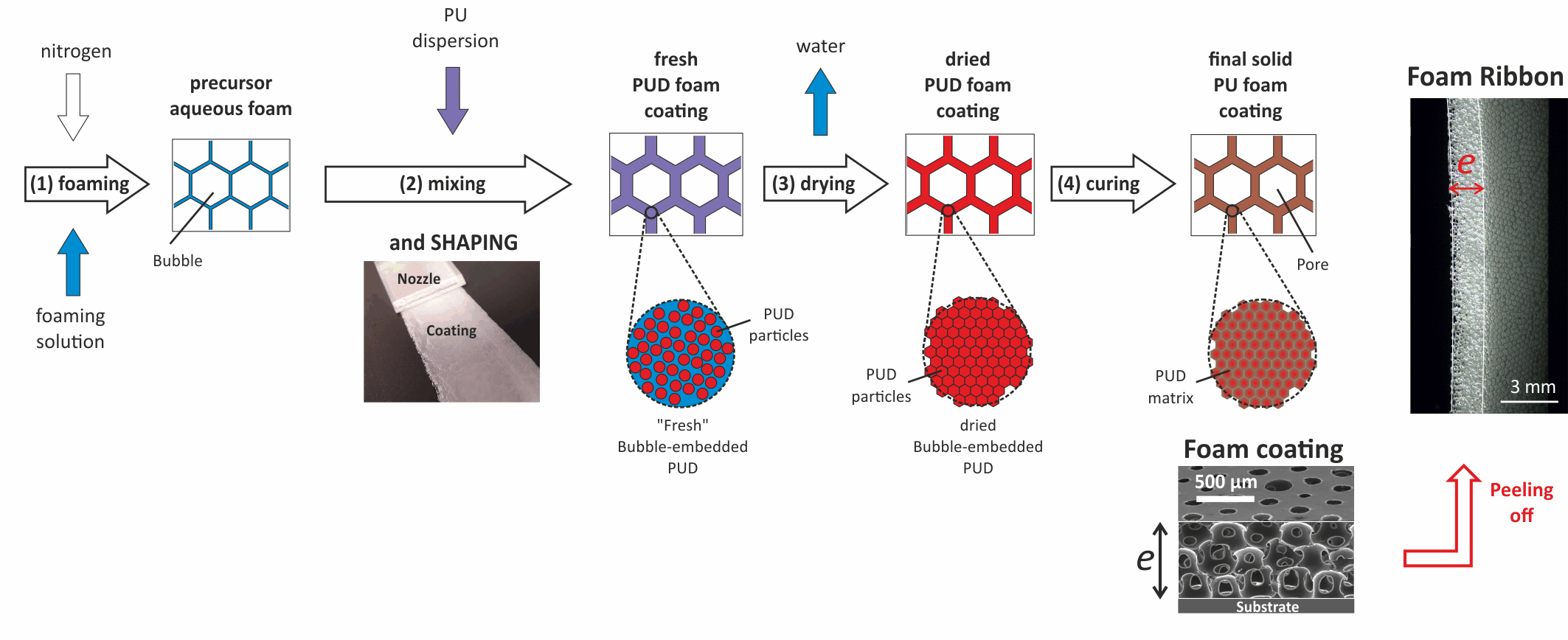

Foam-based solid coatings appear to be a simple solution for giving new properties to solid surfaces. During the PhD thesis of Aymeric Mouquet (2015-2018), an efficient method was developed to produce open-cell foam coatings having a tunable pore radius distribution (i.e. monodisperse within the range 100–1000 mm, bidisperse or fully polydisperse), tunable thickness, and tunable bulk and surface porosities. This was achieved by mixing a precursor aqueous foam and particle suspension (here a micrometer-sized polyurethane dispersion), and by spreading with a nozzle the resulting particle-loaded foam on the solid surface to be coated. It was shown that the bubble size distribution of the precursor foam can be preserved in the final solid coating. This was highlighted by using monodisperse aqueous foam, for which coatings showed a polycrystalline structure, as well as bidisperse or fully polydisperse foams. As a major advantage of our method, the bubble size and solid volume fraction are shown to be independent parameters, allowing the size of the microstructural elements to be tuned easily, and so the expected functional properties of the coating. Results obtained with the studied polyurethane dispersion are expected to be reproduced with other dispersions.

Little was known about the mechanics of foam systems characterized by a small number of pores across their thickness and possessing parietal or free surface pore layers. Elastic stiffness and rupture stress have been measured for open-cell foam ribbons produced thanks to a method allowing to tune finely and independently several crucial parameters: ribbon thickness, pore size and solid volume fraction. Results revealed that the longitudinal elastic stiffness of foam ribbons increases significantly as the number of pores across the ribbon thickness decreases within the range 1-10. This increase was understood through the contribution of the parietal layers with respect to the bulk layers. Similarly, rupture stress of foam ribbons characterized by narrow pore size distributions increases as a function of the ratio pore size/ribbon thickness. All others things being equal, the rupture stress is smaller for polydisperse samples compared to monodisperse samples.

Related Papers:

– Well-controlled foam-based solid coatings, A. Mouquet, Y. Khidas, T. Saison, J.-Y. Faou, O. Pitois, Soft Matter (2019) 15, 5084-5093

– Tensile mechanics of polymeric foam ribbons, A. Mouquet, Y. Khidas, X. Chateau, T. Saison, J.-Y. Faou, O. Pitois, Polymer Testing 86 (2020) 106513