Our research group has investigated liquid foams, interfaces and soap films for over a decade. We focus on the mechanical stability of thin liquid films, granular films and gas marbles. We are also interested in the rheology, the coarsening and the stability of simple bubbly media or complex aerated materials, along with the production and the shaping of foamed coatings and foamed construction materials.

Coarsening of liquid foams

O. Pitois, N. Galvani (PhD)

Collaborations : S. Cohen-Addad, R. Höhler (INSP), D. Langevin, E. Rio, A. Salonen (LPS), D. J. Durian (U. Pennsylvania), S. Vincent-Bonnieu (ESA)

In liquid foams, we name coarsening the gas diffusion from one bubble to another through the liquid that separates them. Coarsening leads to a decrease in the number of bubbles and to an increase of their average size. While many applications deal with wet foams, i.e. with a liquid volume fraction above 20%, these foams have been seldom studied because of their instability to liquid drainage due to gravity.

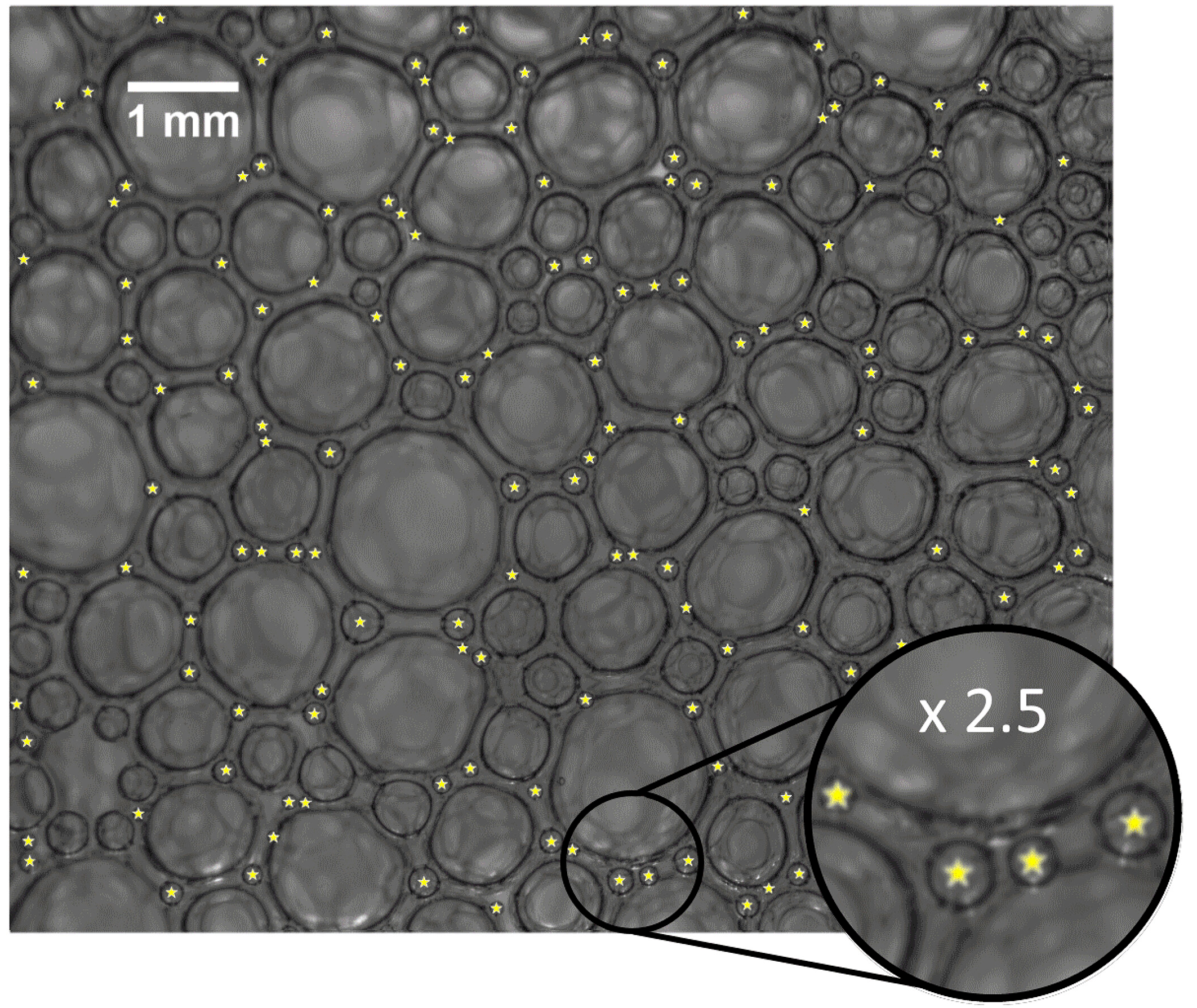

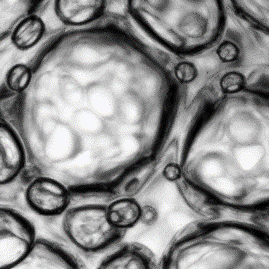

We have joined a European consortium led by Dominique Langevin in the framework of a MAP Contract (Hydrodynamics of Wet Foams) with the European Space Agency to study liquid foam coarsening on the International Space Station (!). The first round of experiments conducted in 2020 have yielded precious results related to the bubble growth dynamics for a broad range of liquid volume fractions from wet foams to bubbly liquids (50 %). We have observed a change in the coarsening regime from a growth with t1/2 for small liquid fractions to t1/3 for the larger liquid fractions. One of our main results is that the volume fraction for which the change of regime occurs (0.39) is laregly above the Random Close Packing volume fraction (0.31 as the foams are not monodisperse). We have shown that this deviation is caused by small adhesion forces that keep the average contact area between bubbles to a non-zero value beyond Random Close Packing. We have also highlighted an excess of small bubbles (named roaming bubbles) in the bubble size distribution compared to theoretical models. We have shown that these bubbles have lost contact with the foam bubbles, which impedes their dissolution. These roaming bubbles had never been seen before.

Credits : ENPC, Ingenius

References

- Hierarchical bubble size distributions in coarsening wet liquid foams, N. Galvani, M. Pasquet, A. Mukherjee, A. Requier, S. Cohen-Addad, O. Pitois, R. Höhler, E. Rio, A. Salonen, D. J. Durian and D. Langevin, PNAS 120 (38), e2306551120 (2023)

- Coarsening transitions of wet liquid foams under microgravity conditions, M. Pasquet, N. Galvani, A. Requier, S. Cohen-Addad, R. Höhler, O. Pitois, E. Rio, A. Salonen and D. Langevin, Soft Matter 19, 6267-6279 (2023)

Granular Films and Gas Marbles

F. Rouyer, Y. Khidas, P. Gauthier (PhD)

Collaboration : A. Seguin, G. Gauthier (FAST)

There are multiple, important applications for systems presenting liquid interfaces containing adsorbed solid particles : decreased surfactant usage, reinforcement of bubbles in aerated construction materials, and froth floatation or encapsulation for environmental remediation processes.

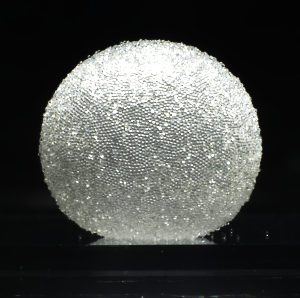

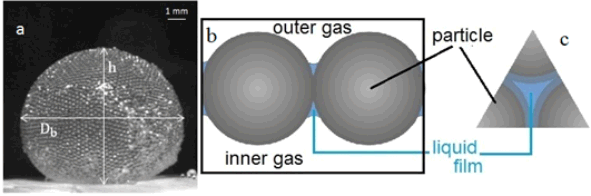

The ANR project PhyGaMa (2020-2024, in collaboration with Laboratoire FAST) is dedicated to studying gas marbles, a new object discovered in the laboratory. Gas marbles are pockets of gas surrounded by a closed envelope of liquid and adsorbed solid particles which are a few tens of micrometers in diameter. In this object, the liquid is under a slight depression, which confers capillary cohesion to the grains and an unexpected mechanical resistance. We coined the term gas marble in reference to liquid marbles that were discovered in 2001.

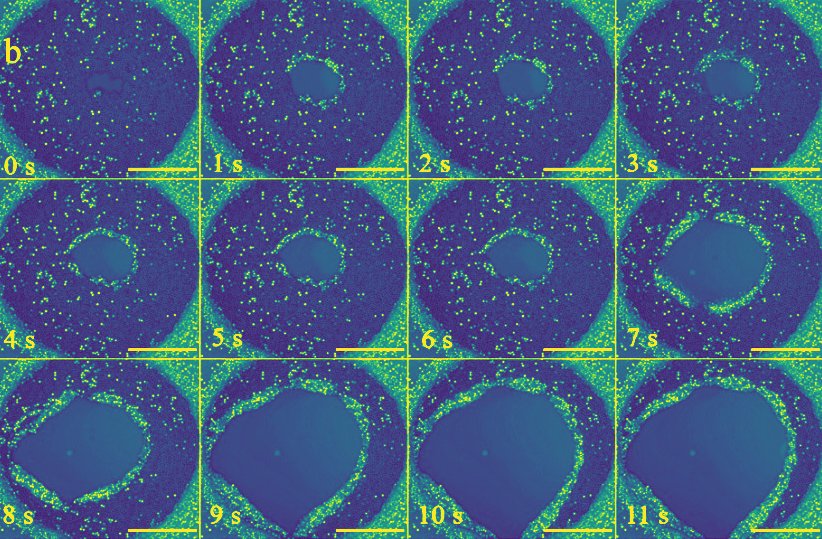

Anatomy of a gas marble, and geometry of the liquid films at its surface

We have developed an experimental setup for which we control the liquid film pressure to study the cohesion properties of the particle-laden liquid film. We have shown that the capillary underpressure determines the response of the envelope when it is being punctured. Under a critical underpressure, we observe a total opening of the envelope similar to traditional soap films; however, the opening dynamics is much overall much slower than simple soap films (Taylor-Culick opening) due to inertia. For higher liquid underpressure, the envelope has a solid behaviour and the puncture hole remains stable. Between the two regimes, we note the presence of an intermittent opening regime. Numerical simulations conducted using Surface Evolver have shown that the cohesive Mohr-Coulomb failure criterion characteristic of granular media explains the observed transition, which sheds a new light on the mechanical stability of gas marbles.

Intermittent opening of a granular film for a liquid underpressure ΔP ≅ – 100 Pa

References

- Gas Marbles: Much Stronger than Liquid Marbles, Y. Timounay, O. Pitois and F. Rouyer, Physical Review Letters Phys. Rev. Lett. 118, 228001 (2017) | ❦ Editor’s Suggestion & Featured in Physics

- Pressure threshold for inhibition of dense granular film opening, N. Retailleau, Y. Khidas and F. Rouyer, RSC Advances, 13, 30905-30914 (2023)

Stability of Foamed Yield-Stress Fluids

O. Pitois, B. Saint-Michel, N. Galvani (PhD)

Collaboration : S. Cohen-Addad (INSP)

[Under construction]

References

Foamed Construction Materials

O. Pitois, V. Langlois, A. Kaddami (PhD), M. Ceccaldi (PhD)

Collaborations : M. Guéguen (CPDM), Y. Péchaud (LGE)

Cementitious Foams

Cementitious foams offer many advantages compared to traditional concrete considering its low density — and then its small carbon and material footprint — and its remarkable thermal and acoustical damping properties. We have produced several samples of cementitious foam with a controlled structure to better understand how the cement morphology affects the resulting foam properties. To do so, we have met the following challenges:

- Formulate a fresh cementitious foam with a controlled structure. We need a good understanding of the interaction between the surfactants required to produce the foam and the cement paste. Some surfactants do not stabilise the foam under very alkaline (basic) conditions. Other surfactant, notably anionic surfactants, adsorb onto the grain surface and alter their interactions: they eventually modify the yield stress of the cement paste. When the surfactant concentration is low, the cement grains become hydrophobic and induce attractive interactions between cement particles, resulting in an increase of the yield stress of the material. In contrast, at higher surfactant concentration, the micelles adsorbed onto the grains induce steric repulsion and the yield stress of the material drops. We have then studied the mechanical resistance of fresh cementitious foams for an air content of 83%. For each data series, we have modified the cement paste yield stress through the addition of superplasticisers or large amounts of anionic surfactants. Surprisingly, the most stable formulations are also the ones with the lowest yield stresses. Meticulous rheology measurements have shown that this stability originates from a collective reorganisation of cement grains towards denser arrangements between the bubbles.

- Maintain the produced structure when the cementitious foam is setting and curing. This part has been studied during the PhD thesis of Blandine Feneuil (2015-2018). We have studied the influence of the bubble size, the water/cement ratio and the surfactant content on this stability. We have then formulated a stability criterion for these materials based on the bubble size and the yield stress of the interstitial cement paste.

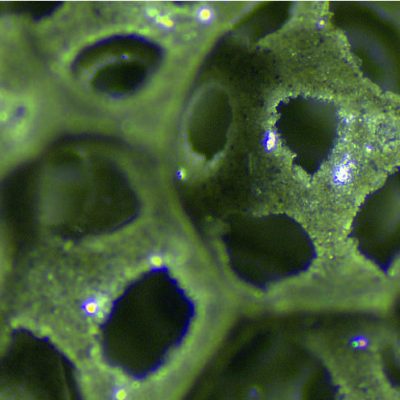

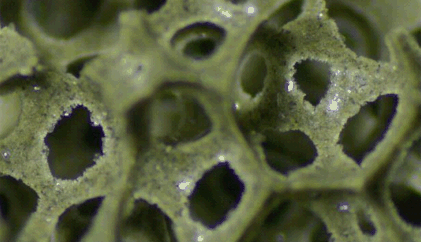

Geopolymer Foams

Geopolymer foams are promising materials since they combine excellent isolation efficiency, good fire resistance and mechanical loads, whereas their carbon, material footprint and overall density are very low. Controlling the pore size in these media remains challenging since the foam ages before the geopolymer sets. During the PhD thesis of Asmaa Kaddami (2016-2019), we have studied a mixture of metakaolin suspension with an aqueous foam precursor. We have presented a physical approach to limit aging phenomena in fresh geopolymer foams and maintain the pore morphology that was initially formed. We have shown that ripening arrest is achieved when the particle concentration in the continuous phase exceeds a critical value that depends on the bubble size and the gas volume fraction. We have explained this value in the framework of the jamming transition which occurs in the metakaolin suspension when it is confined in the foam network. Confinement effects confer a finite elasticity to these granular packings against bubble movement. This very general result allows us to master the morphology of geopolymer foams of industrial interest.

Bio-calcifying foams

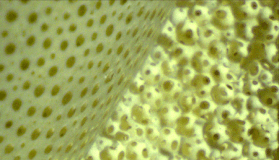

The PhD thesis work of M. Ceccaldi has focused on the formulation of bacterial, bio-calcifying liquid foams to induce Calcium Carbonate (CaCO3) precipitation (MICP). The best-performing formulations are based on the Sporosarcina pasteurii bacterium strain and surfactants of the APG (Alkyl Poly Glucosides) family bearing two glucose (maltosides) functions. We have shown that pumping such a foam in a granular packing indeed results in CaCO3 precipitation around the contacts between grains, whereas the impact on the material porosity remains limited. We still have to evaluate the mechanical performance of materials produced using this process that we named FoamMICP.

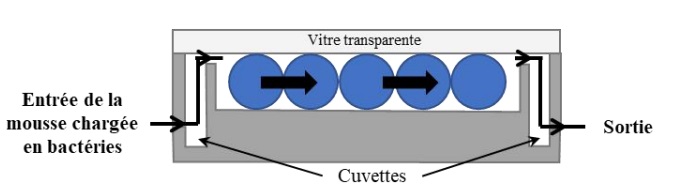

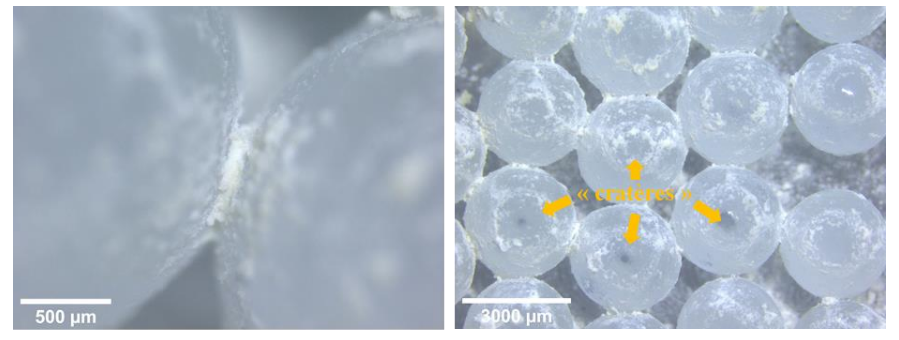

(Upper panel) : bio-calcification setup of a particle stack. We pump a bio-calcifying foam loaded with bacteria in this geometry before waiting. (Lower panel): CaCO3 formation between particle pairs after four bio-calcifying rounds.

References

- Effect of surfactants on the yield stress of cement paste, B. Feneuil, O. Pitois, N. Roussel, Cement and Concrete Research 100, 32–39 (2017)

- Stability criterion for fresh cement foams, B. Feneuil, P. Aimedieu, M. Scheel, J. Perrin, N. Roussel, O. Pitois, Cement and Concrete Research 125, 105865 (2019)

- Formulation de mousses bio-calcifiantes pour la production de matériaux poreux, M. Ceccaldi, Thèse de Doctorat (2023)