Contact : Cédric Mézière

Missions

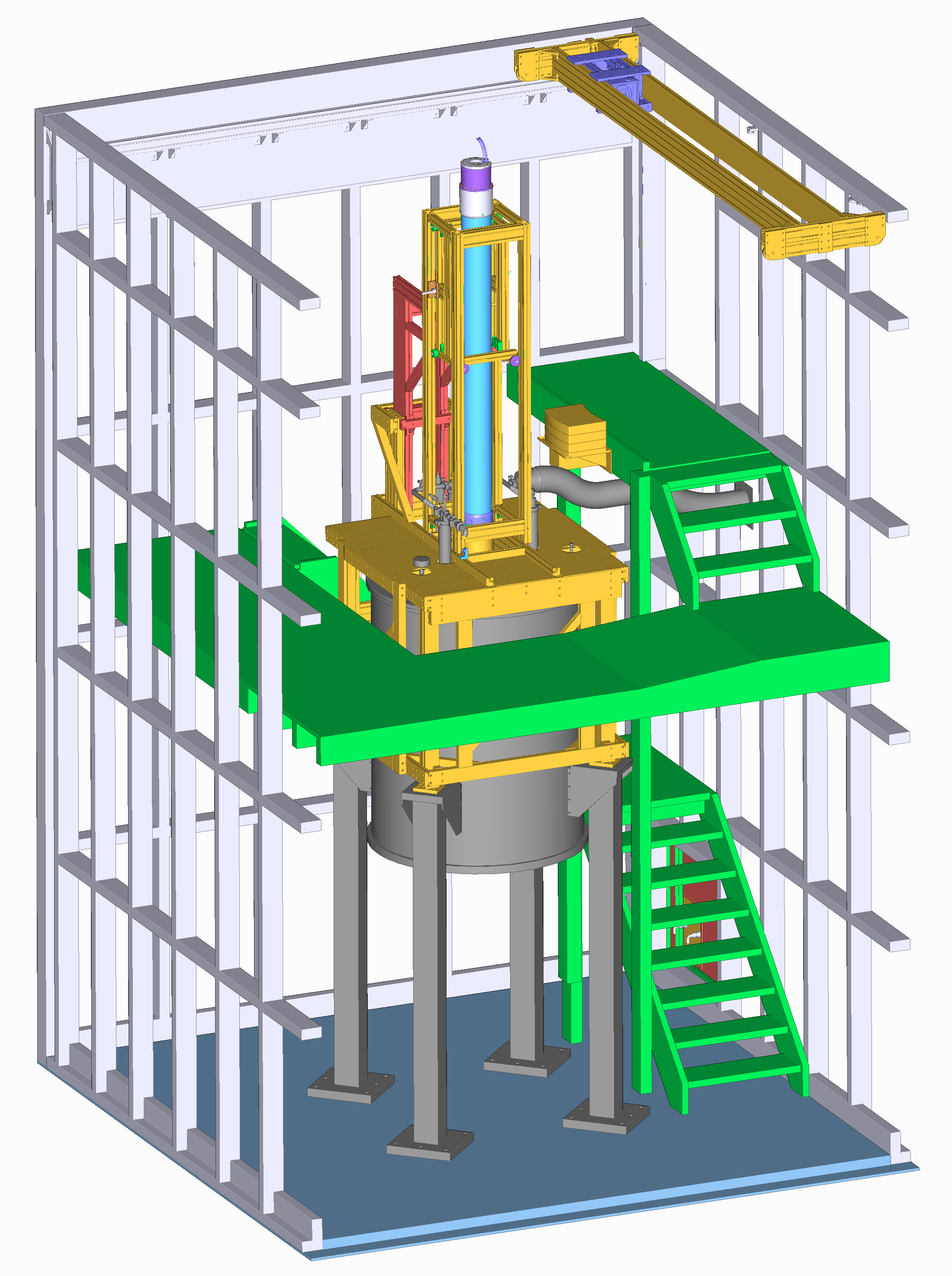

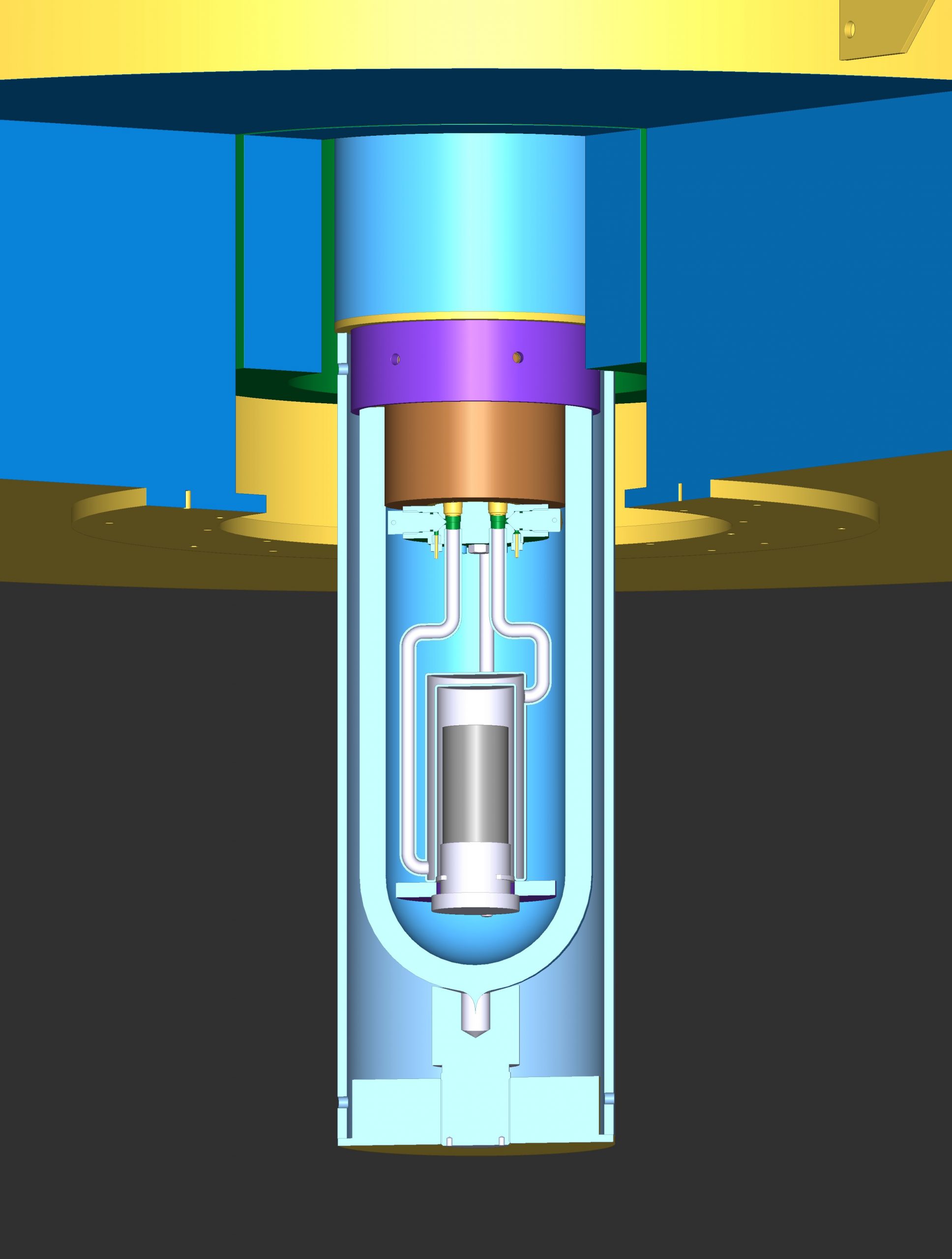

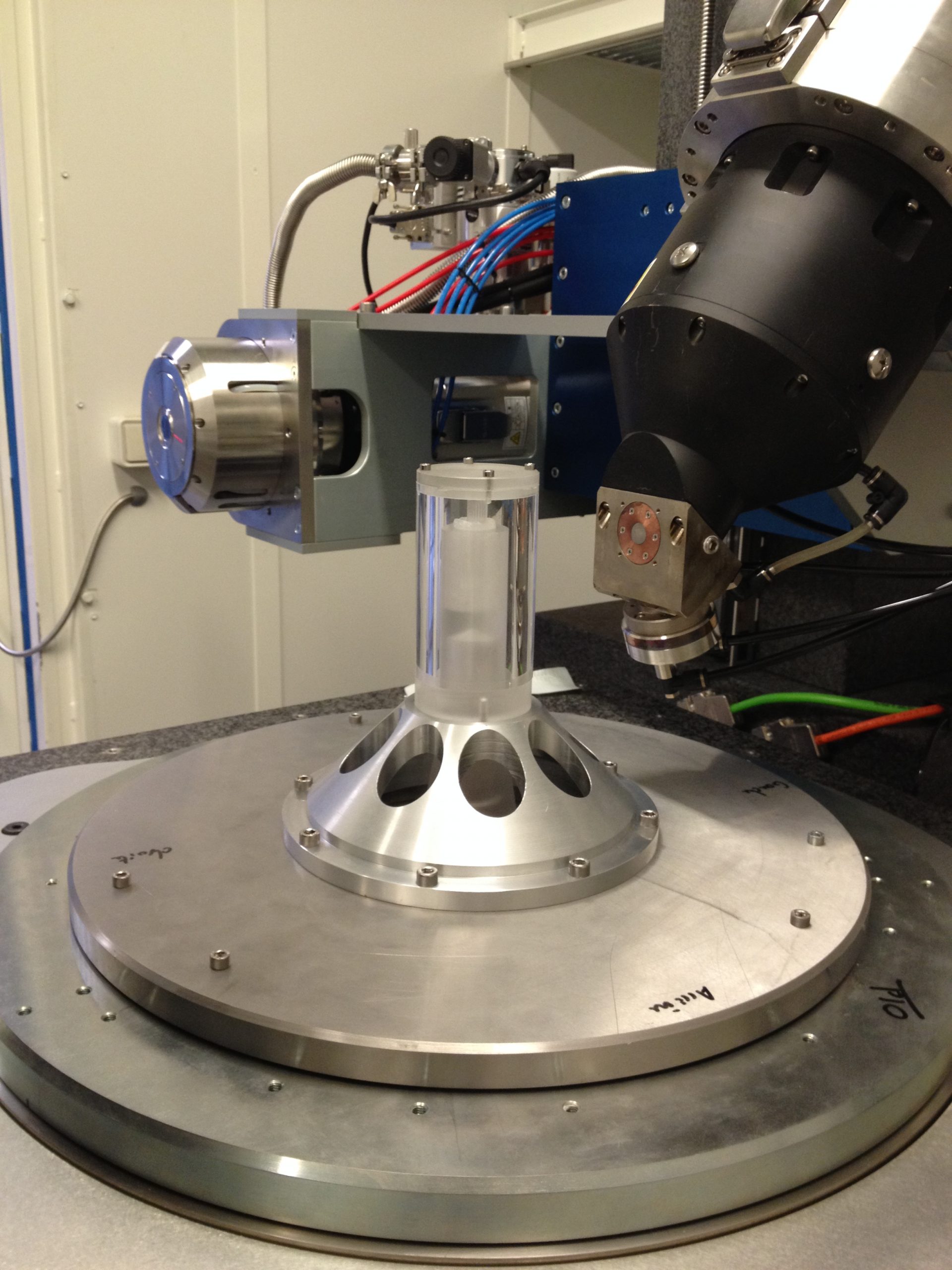

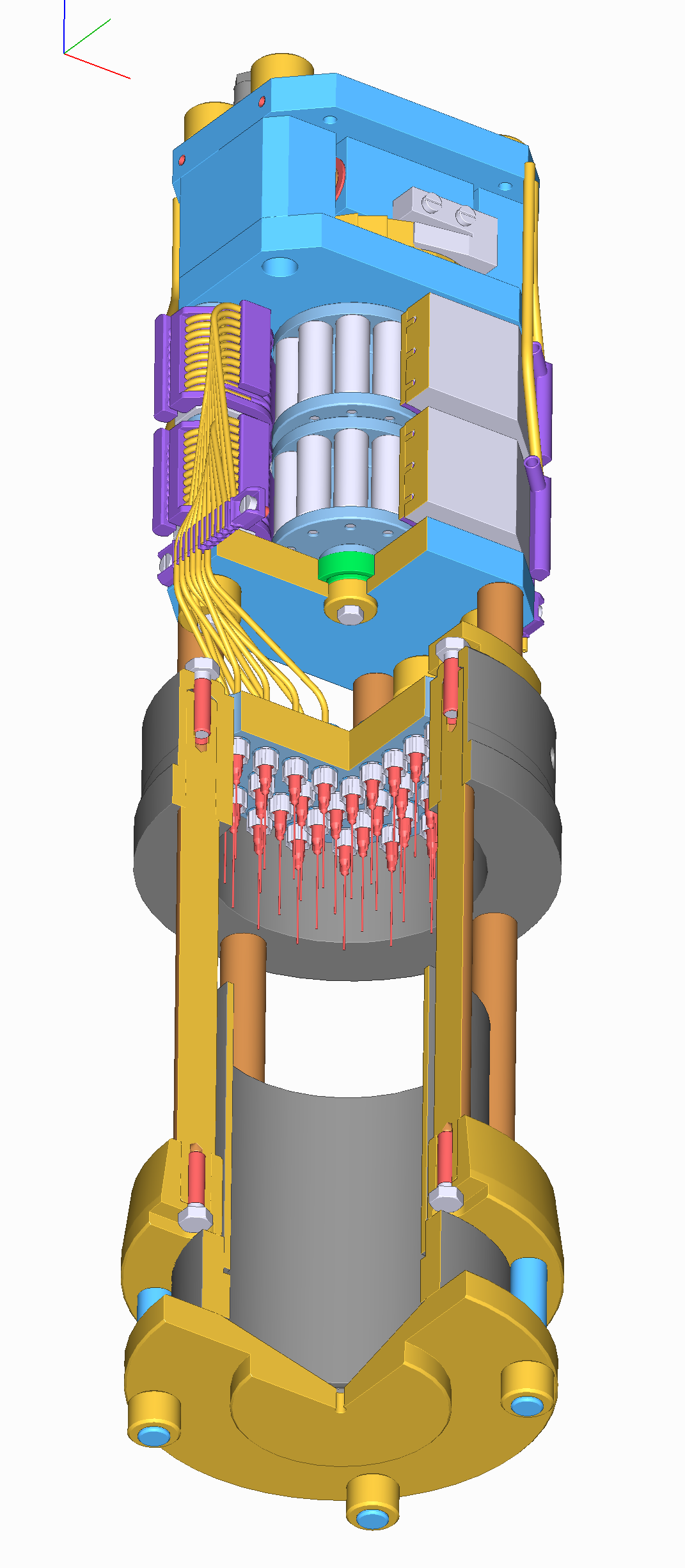

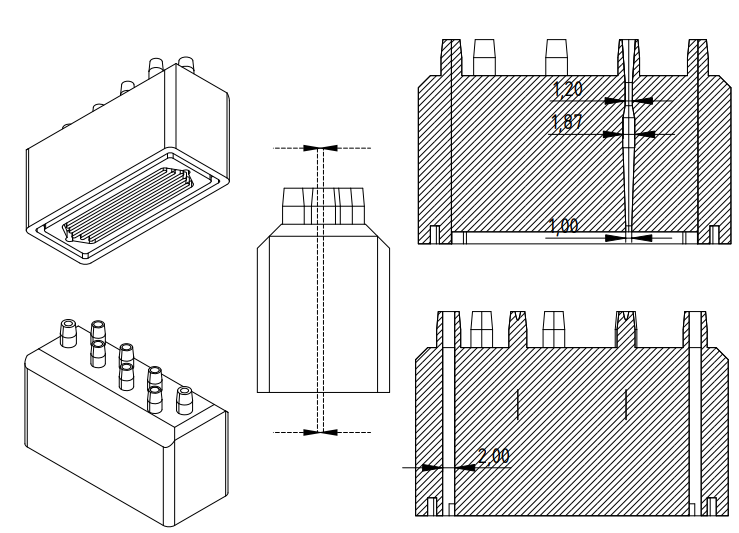

The transversal technical team (ETT) is responsible for the design, manufacture, implementation, maintenance and monitoring of infrastructure elements and experimental devices. It responds to requests concerning all experimental rooms and more particularly, platforms coupled to the Magnetic Resonance Imager and to the X-ray micro-tomograph. Its role is to adapt test machines and develop original, modular and ergonomic devices integrated into large instruments. It has developed skills and know-how to respect the specific constraints of imagers and insertable devices.n X.

Capabilities

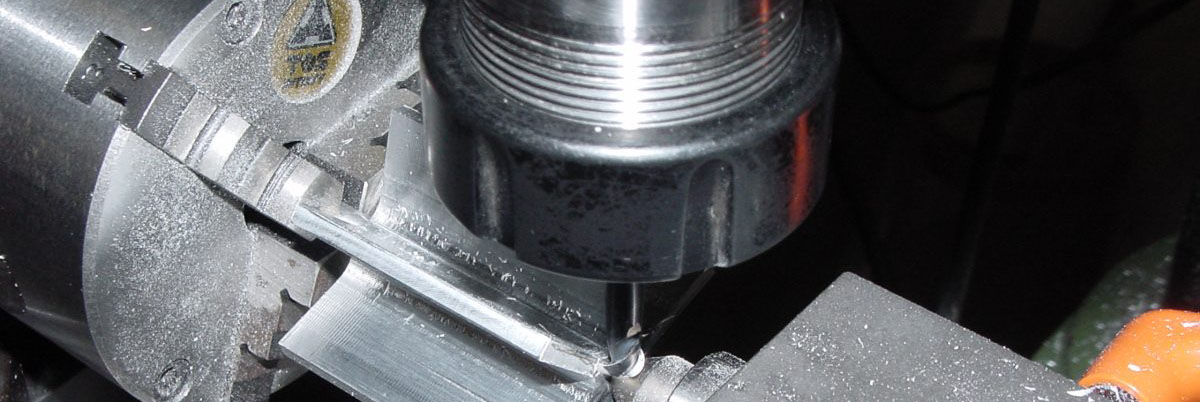

Machine Tools

The mechanical manufacturing workshop is composed of a semi-digital lathe with a maximum diameter of 250, length 700 (dimensions in millimeters), a conventional milling machine with a capacity of 750x300x470. But also drill presses, power saws, grinders and a large stock of raw materials. The editing room is equipped with a 70 × 200 marble with dedicated screws and hardware. The electronic part is equipped with a complete workstation and a printed circuit burner.

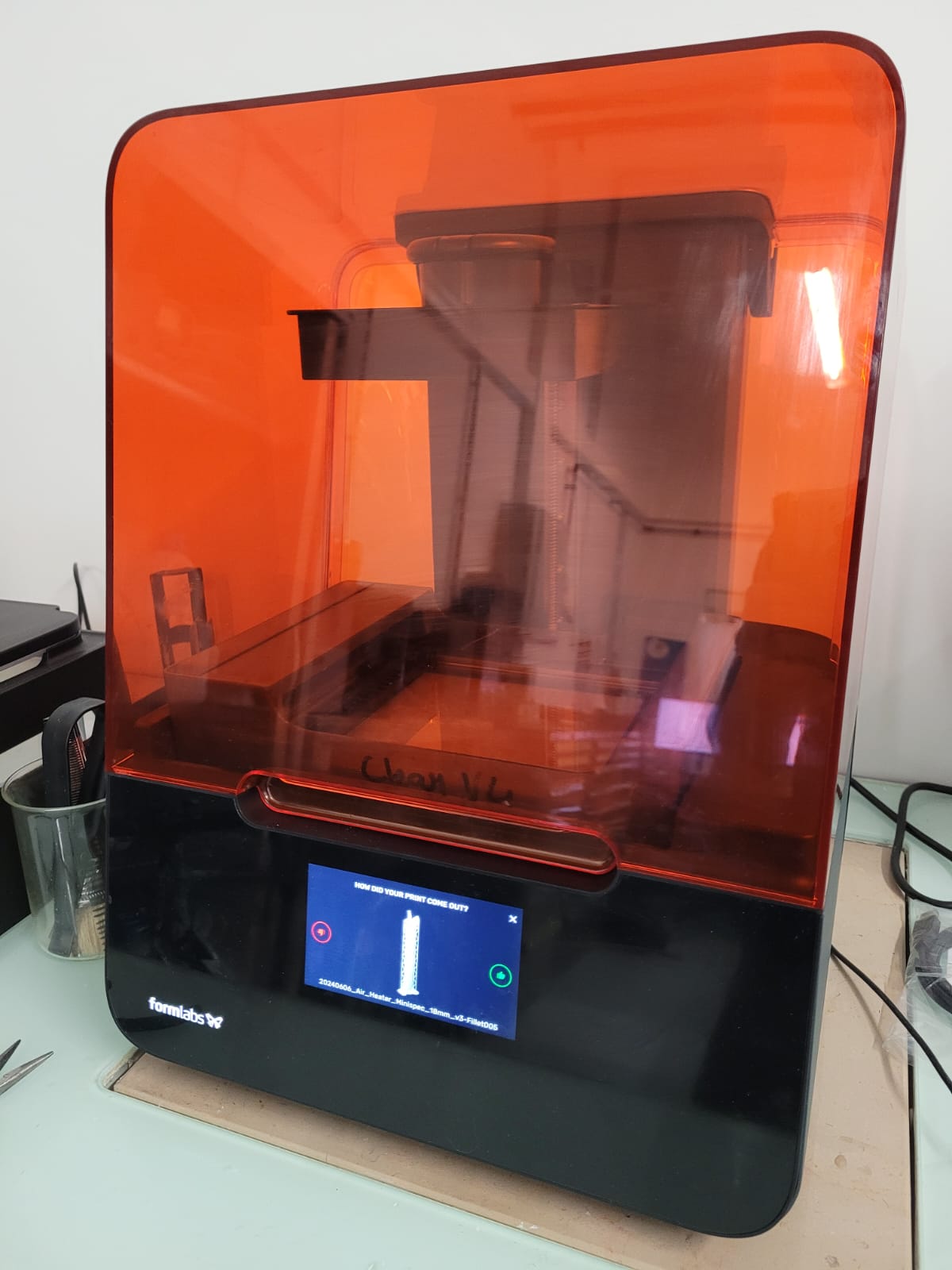

3D-Printing Solutions

Besides its filament-based (FDM) 3d printing solutions, the ETT has recently bought a Formlabs Form 3+ stereolithography-based (SLA) 3d printer with an isopropanol bath and an ultraviolet oven. It prints transparent pieces with a much better precision (around 50 µm) than FDM solutions.

Achievements and set-ups

Since January 2008, the ETT has completed more than 100 projects. On the one hand, on the imaging platforms: MRI: 5 infrastructure elements and 13 experimental devices, Micro-tomograph: 2 infrastructure elements and 2 experimental devices. On the other hand, on the experimental devices of the research teams: 65 in Rheophysics and Porous, 10 in Multi-Scale, 4 in MSA, 1 in Geotechnics. ETT members are cited 20 times in HAL.